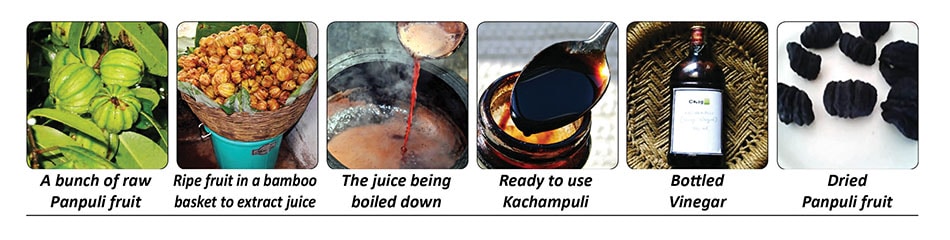

It is monsoon season in Kodagu and though rains are less this year, people in remote villages of Kodagu, who have grown Garcinia gummi-gutta tree in their estates or have access to the tree grown in the wild, are busy in preparing Kachampuli, the dark, tart vinegar. Kachampuli preparation has been passed on from generations and is indispensable in Coorg cuisine. Every Coorg kitchen has a couple of bottles, or more, of Kachampuli tucked away at the corners or stored in the attic. This Weekend Star Supplement introduces readers to this enigmatic liquid and explains the process of obtaining it from yellow fruits hanging on top of tall trees.

Kachampuli: The Quintessential Coorg Condiment

A full-fledged processing unit at Ponnampet Forestry College

By B.C. Thimmaiah

Souring agents are an integral and inseparable part of our culinary traditions. Depending on the State and community, souring agents vary. Apart from lip-puckering tamarind and lime juice that is quite ubiquitous in most Indian dishes, there are a host of other souring agents that enhance the flavour of dishes like Kodava Pandi Curry (pork curry) where Kachampuli makes it the ‘Dish with a Zing’.

The concentrated juice is obtained from Garcinia gummi-gutta, the same fruit that is used in dried form in parts of Kerala, where it is known as punampuli or kodampuli/kudampuli. It is a relative of kokum, which is used in Mangalorean, Konkan and Maharashtrian cuisines. In Kodava language, the fruit is known as ‘Panpuli’ and its boiled extract is ‘Kachampuli’.

The fruit is like a large Amla but with prominent sections. In its fresh form, it is known to possess medicinal properties and is the basis for many weight-loss products. The English name is Brindle Berry. Before it is stored, the Panpuli is taken apart in slivers, dried and then smoked. It’s here that the green fruit turns into matt black. Later, dry pieces are soaked in warm water and torn apart before being added to the curry.

Juice preparation process

In Kodagu, the fruit is left out in baskets until the pulp breaks down. A large vat is kept below to collect the juice and the pulp is removed. The juice at first is pale and golden. It is then boiled in large clay pots until it turns dark burgundy in colour. This slow heating turns it into a syrupy vinegar. The final result is a dark and thick liquid and this liquid extract is known as Kachampuli.

Interestingly, Kachampuli improves with age. The older brews are preferred over the newer ones for cooking. The new bottles are usually stored in attics in Kodagu and are left there to mature and attain that perfect texture, taste and colour. Kachampuli is usually used in the final stages of cooking, mainly in meat and fish dishes, most famously in Pandi Curry and fish curry.

An expensive commodity

While Kachampuli was abundantly available in the open market earlier, now it is a scarce and an expensive commodity even in Kodagu, its hometown, thanks to the present generation that is unwilling to take the trouble of preparing it as it is a long-drawn and pain-staking process. Adulteration of Kachampuli to make a quick buck too has become rampant.

Realising Prime Minister Narendra Modi’s ‘Make in India’ initiative

Considering the rarity of the fruit and its many uses, College of Forestry at Ponnampet in South Kodagu has started a full-fledged unit that procures the Garcinia gummi-gutta fruit from farmers, processes it, prepares Kachampuli and then markets it. This initiative has not only ensured that the tradition continues but also eased the scarcity of the unique product in the market.

The initiative at the College was started by former Dean of the College Dr. B.C. Uthaiah and continued on a major scale by the present Dean Dr. C. G. Kushalappa, who has conducted extensive research in Devarakadus, the Sacred Forests of Kodagu and the wild and edible fruits of Kodagu, and Dr. B.N. Satish, Assistant Professor, Department of Forest Products and Utilisation.

Hands-on Training

The College is following the traditional methods of using forest produce available in Kodagu. “Our College offers Hands-on Training (HoT) programme to add value to non-timber forest produce where wild and edible fruits of Kodagu like Garcinia gummi-gutta, gooseberry, kokum and Karada (karmunji in Kodava language) fruit are made into products including pickles, jams and jellies, candies, squash, toffees and, of course, Kachampuli. This apart, we do produce hair care products from soap nuts and agarbathi. These exotic products are marketed under Sayhadri Brand,” says Dr. Kushalappa.

“This initiative is completely agriculture-and-farmer-oriented and we want to tell our farmers that their products have value and market. We provide plantation material or saplings, standardise production, maintain quality and focus on effective waste disposal. We have procured Government of India-manufactured machines from Coimbatore and we have a larger plan to set up Small Scale Industry production units at Ponnampet,” he explains.

Efforts to retain youths from migration

Basically it is to retain the youths in Kodagu who are migrating to cities in search of job opportunities. “We want to tell them that they can lead a comfortable life by adopting innovative farming and cultivate such unique fruits in a large scale as Kodagu is a natural zone under Western Ghats for such fruits. Our intention is to make them self-reliant. It is our way of nation-building aligning with the theme of Prime Minister Narendra Modi’s Make in India initiative,” he rues.

“It is an entire world out there when it comes to wild berries and there is a huge market. For example, Garcinia gummi-gutta extract by multi-national companies is sold in the US and Europe as bio-slim products. We are trying to tie up with institutes like Central Food Technological Research Institute (CFTRI) for product development,” Dr. Kushalappa explains.

Grafted trees for high yield

Apart from producing the actual and authentic Kachampuli, the College supplies Garcinia gummi-gutta saplings for large-scale cultivation. “It is a huge tree and no coffee plant can grow under it. Our grafted tree does not grow that tall and growers can take up integrated coffee and Garcinia gummi-gutta cultivation. Our saplings are short and gives a high yield,” he reveals.

On the Kachampuli product marketed by the Forestry College, Dr. Satish says that the product is made in a traditional way with the use of modern techniques. “It is free from any sort of adulteration and we have not used any preservatives. There is a great demand for the product from both residents of Kodagu and the natives who live outside the district,” he says.

One tree, many fruits, multiple uses

The Garcinia gummi-gutta is a small or medium-sized tree and the bark of the tree is grey, smooth and contains abundance of bright-yellow gamboges (a gum resin produced by various trees, used as a yellow pigment and in medicine as a purgative). The tree starts bearing fruits when it is eight-years-old and it continues to bear fruits till it reaches 40 to 45 years. The fruits are two to three inches in diameter and are yellow when ripe with six to eight grooves. One tree can yield 100 to 125 kgs of fruit.

Around 25 kgs of Garcinia gummi-gutta fruit is required to prepare one litre of Kachampuli with an investment of Rs. 300 to Rs. 350 per litre. Once the product is ready, it can be sold up to Rs. 1,500 per litre.

There will be six to eight seeds surrounded by a succulent aril (an extra seed covering, typically coloured and hairy or fleshy). Usually, the Garcinia gummi-gutta flowering takes place from February to May every year and from June to August it is fruiting season and that’s the time when people of Kodagu get on to prepare the famed Kachampuli.

Uses of Garcinia gummi-gutta fruits

The Garcinia gummi-gutta fruits are edible, but too acid to be eaten raw. They are valued for their dried rind which is used in Travancore-Cochin and Malabar as a condiment for flavouring curries in place of tamarind or lime. In Sri Lanka, the fruits are picked under-ripe, the thick pericarp cut into sections, dried in sunlight and preserved for future use. The dried material is used along with salt in the curing fish. The edible oil extracted from the seed resembling kokum butter is used extensively in preparation of the local dishes.

Apart from using the fruit and its extracts for food purposes, the raw and processed rind of the fruit is extensively used as a condiment, coagulant and for polishing gold and silver articles. The Garcinia gummi-gutta seed is an edible source of fat and interestingly the tree does not have any pest or disease and is a characteristic trait of the tree family. The fruit is also used in Indian traditional medicine for edema, delayed menstruation, constipation and other intestinal disorders.

Recent Comments