Dreamweavers of a quaint village near Srirangapatna who wove clothes for Mysore royal family and Tipu Sultan

By Vinay Karekura

Kodiyala, over 20 kilometres from Srirangapatna, is like any other quaint village of ‘Mysuru Seeme’ with small pillared houses on either side of narrow roads dotted with petty shops selling tea and bakery biscuits where a single room with two wooden chairs and a bench serves as a men’s salon; where there are shops sporting old-fashioned name boards and selling vegetables and Kirana items. What makes Kodiyala distinct is that the entire village is a tightly woven network of weavers’ community and every household indulging in one or the other form of weaving — handloom to powerloom or from cotton to silk. Kodiyala sarees and dhotis are in great demand in local as well as global market.

Enter the lanes and one can hear click-clack sound at regular intervals so also the sound of machines. The village is etched in the history of Mysore as weavers here wove clothes for the royal families of Mysore and Tipu Sultan.

This village is home to hundreds of ‘Padmashalis’, a Telugu-speaking weaver community known to have migrated from Andhra Pradesh hundreds of years back. The term ‘Padmashali’ is derived from two words ‘Padma’ and ‘Shali’ — ‘Padma’ means lotus and ‘Shali’ means weaver. The word ‘Padmashali’ refers to the myth of the thread was a lotus which sprang from the navel of Lord Vishnu.

Family legacy

Notably, the tradition that has been passed from generations is being continued by the present generations through automation though there are still many hand-operated looms in the village. At Kodiyala, there are over 250 ‘Padmashali’ families continuing their family legacy.

None of the weavers here depend on any kind of publicity. They solely depend on word of mouth and customer trust. 90 percent of the buyers are repeat customers and through references, who come from far and wide to buy sarees known for their quality and rich natural vegetable dye.

Walk through the lanes and one can see that every house has a weaver as young as 17 or as old as 70 using the weaving equipment or operating a powerloom. Every second house is a tiny retail shop with interested customers looking for their choices and the families of weavers eagerly displaying the sarees. At the centre of the village is ‘Kambada Mane’ (pillared house) that is a wholesale-cum-retail unit for silk sarees where products are sold directly from weavers to customers.

Eye-catching motifs

Traditional weaving is their primary source of income as they produce sarees and dhotis that are rich, colourful, unique in nature and stylish with eye-catching motifs.

Legend says that Tipu Sultan was an admirer of cotton cloth designs produced at Kodiyala and he ordered clothes for himself and his entire family. Another legend says that it was Tipu Sultan who brought a set of weavers from Hyderabad to Kodiyala. Eventually, the Mysore royal family members too fancied these intricately woven sarees and it became a part of royalty.

Usually it takes three to four days to complete a saree with one to three weavers working on it. Now the job is made easy with the introduction of powerlooms. When S.M. Krishna was the Chief Minister, he brought in modern powerlooms to the village and connected them with Thoobinakere powerline.

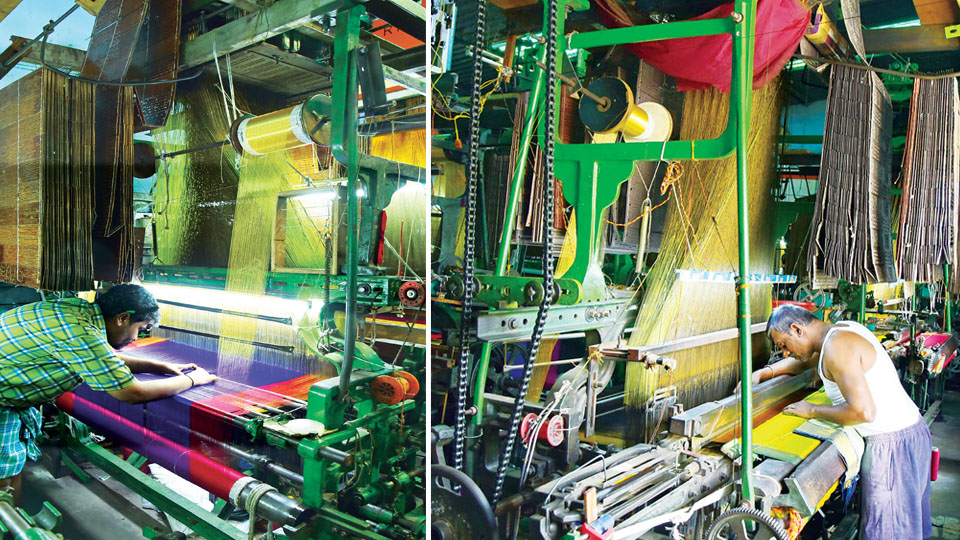

The machines housed inside dimly-lit rooms rarely rest. These powerlooms can churn out many sarees per day with minimal human intervention. Still, there are some families who continue to weave in hand-operated looms.

Modern touch

Powerlooms are computerised and enable weavers to create trendy designs to suit the requirement of women. The designs are stored in memory cards and accessed by the control panels installed in the looms. Powerlooms offer speed, accuracy and efficiency with minimal human interference, thereby reducing the costs and increasing profit margins.

Only natural or organic dyes and vegetable colours — colours from carrots, mangoes, beetroots, moringa leaves, jamuns and oranges — are extracted, processed and used for dyeing the threads. Weavers go to small factories in Bengaluru for colour extraction process and they dip the threads in the colour for days so that even if the saree is washed, the colour remains intact.

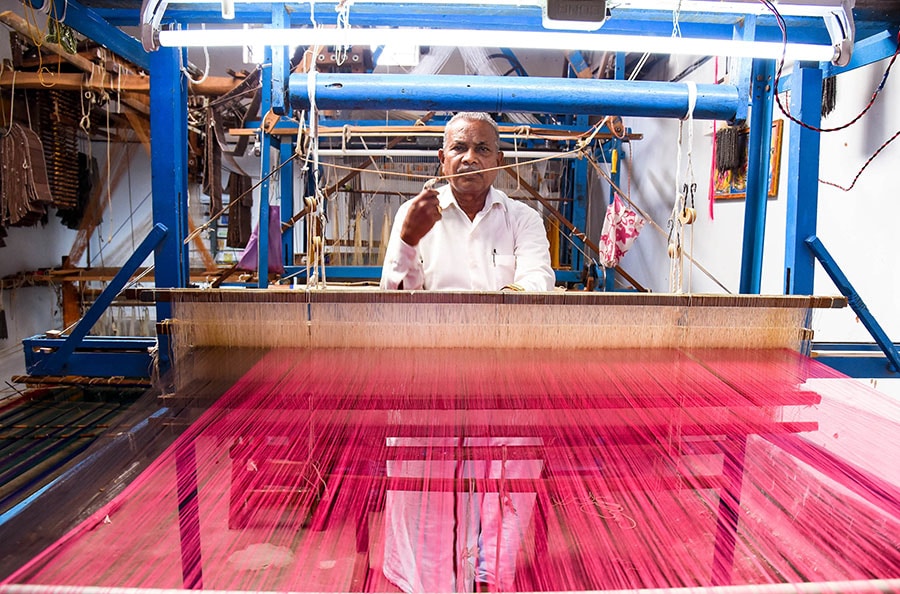

Love for handlooms

Speaking to Star of Mysore, Govindaraju, who is known as ‘Kodiyala Gandhi,’ says that soft yarns are processed naturally without any chemical treatment. He still works on handloom and he has been doing this since 38 years.

Our sarees are hassle-free as they require neither pressing nor dry cleaning. The dyes don’t fade and the sarees last for a lifetime,” he says. Govindaraju, however, has no favourable opinion on powerlooms and insists that hand-woven sarees have the beauty and design that are better than machine-produced ones.

The downside of powerlooms in a handloom cluster like Kodiyala is that many weavers have migrated to cities to produce for the urban mass market. Of the 250 families that currently reside in the little hamlet, barely one percent works with handlooms. A heartening fact, however, is that many youngsters have taken to weaving to continue the tradition. Not only ‘Padmashalis’ but skilled members from other communities too have established handlooms at Kodiyala. So next time you pass by Srirangapatna, don’t forget to take a peek into this weavers’ village.

Recent Comments