- Hubballi Workshop has manufactured 1,612 coveralls while Mysuru Workshop has produced 640 suits

- Each of the Workshops to manufacture 8,400 coveralls in next two months

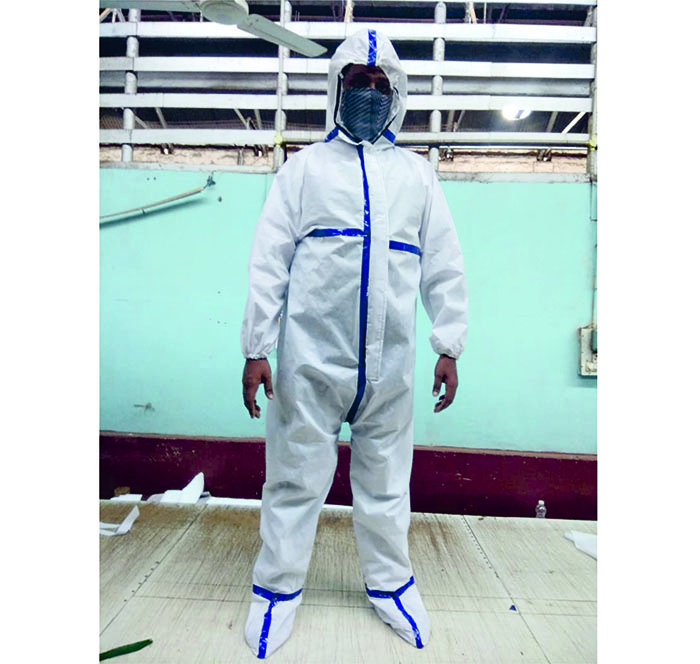

Mysore/Mysuru: Indian Railways Production Units, Workshops and Field Units have started manufacturing Personal Protective Equipment (PPE) coveralls for medical and health-care personnel, who get directly exposed to the COVID-19 disease when working amongst infected patients.

Indian Railways’ Doctors, Medical Professionals, other health workers and care-givers are working tirelessly fighting the COVID-19 disease. As a first line of defence against contracting the Novel Coronavirus, they need to be provided with a special kind of impervious coverall that acts as a barrier to the virus as well as other disease-carrying fluids. As the incidence of COVID-19 increases, even though in a relatively controlled manner, the requirement of PPE coveralls is also multiplying.

Aiding the medical fraternity by providing protective gear as they battle the pandemic, South Western Railway (SWR) has started manufacture of high quality PPE coveralls from Apr.21, 2020 and so far has manufactured 2,252 coveralls as prescribed by Ministry of Health and Family welfare. The SWR Workshops at Hubballi and Mysuru have successfully replicated the high quality PPE coveralls.

Hubballi Workshop of SWR has manufactured 1,612 coveralls. Of these 650 were done in April and 662 coveralls in May. During this month so far 300 coveralls have been manufactured. Mysuru Workshop has manufactured 640 coveralls, 340 during the month of April and 300 coveralls in May 2020.

8,400 coveralls in next 2 months

PPE suits are being manufactured in Workshops of Hubballi and Mysuru under strict quality control as per the established standards. Each of the Workshops are targeted to manufacture 8,400 coveralls in next two months.

In order to fill the gap in availability and requirements of PPEs, Jagadhari Workshop of Northern Railway had taken the initiative to design and manufacture a prototype PPE coverall. The prototype coverall was tested by Defence Research Development Establishment (DRDE) Laboratory of DRDO at Gwalior, authorised for conducting such tests. The coverall samples passed all the tests conducted by DRDE with the highest grades.

All this has been done despite there being a major global shortage of appropriate raw material as well as machinery for manufacturing PPE coveralls. Behind this endeavour is the time-tested capability of Indian Railway’s Workshops and Production Units of manufacturing and maintaining some of the safest Railway rolling stock in the world.

The same capabilities, expertise, protocols and procedures usually followed for design, manufacturing and use of rolling stock, have been utilised for enabling field units and workshops to start manufacturing high quality PPE coveralls so rapidly.

These coveralls will go a long way in equipping doctors treating COVID-19 patients at Divisional Railway Hospital, Bengaluru, with 50 beds and 6 ICU beds and now converted as exclusive COVID Hospital.

Similarly, doctors will also be equipped with coveralls for treating COVID-19 patients at Divisional Railway Hospital, Mysuru, with 74 beds and at Central Hospital, Hubballi with 30 beds converted as isolation blocks and earmarked for COVID-19 patients, according to a press release from the Chief Public Relations Officer, SWR, Hubballi.

Recent Comments