By S. Kenneth Shishir

Mysore/Mysuru: The eco-friendly nature of electric two-wheelers is making their market grow at an incredible pace with a lot of auto-makers rolling out vehicles with eye-catching designs.

Modern scooters trace their heritage as far back as 1895 when first patents for electrically-powered personal transportation devices were filed. However, many are unaware that a company in Mysuru had rolled out over 500 electric mopeds ‘Komal’ way back in 1980-81. The company that manufactured electric two-wheelers in Mysuru was ‘Electromobiles India Limited’.

According to Surya Kumar Kikkeri, the then General Manager of Electromobiles India Limited, the unit was initially started in Dharwad but moved to Mysuru in 1977-78 as land was available here, “The unit was set up at Yelwal and was later shifted to Premier Studio premises on Hunsur Road. It was a Government unit under the ‘Alternative Source of Energy Commission’, with the then Prime Minister Indira Gandhi as its Chairperson.”

Surya Kumar said that trial production started in 1980-81 and the vehicles were sent to Automotive Research Association of India in Pune to get a ‘Road worthy certificate’ and to comply with Motor Vehicle Rules. Though everything was approved and over 500 electric scooters under the name ‘Komal’ were manufactured with more than 10,000 bookings on hand, problems of management and funds cropped up, which eventually hit production.

Except for the motor which was supplied by Honeywell from the USA, all other parts including the batteries were manufactured in India, Surya Kumar said.

“Komal had 12 volts 70 AH battery, which used to give about 70 km per charge and could reach a top speed of 35 to 40 km. There was hardly any major maintenance except for refilling distilled water to the battery,” he added.

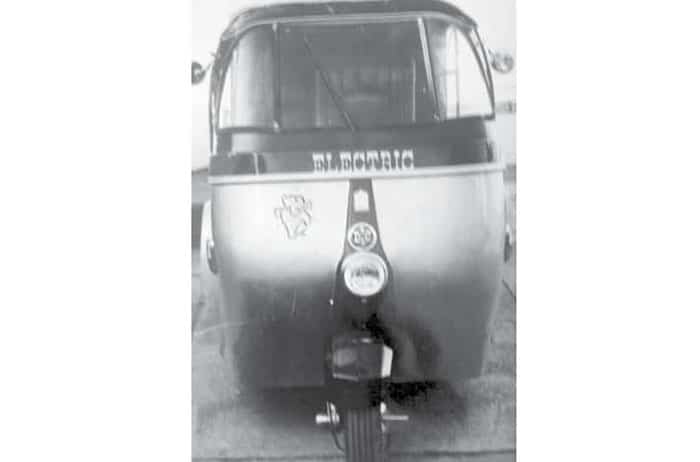

The company had also manufactured three-wheelers (autos), which were used in the 1982 Asian Games from Nov. 19 to Dec. 4 in New Delhi.

“We were the pioneers. Mysuru would have been the first city in the country to produce electric vehicles en masse if more research and development and investment had taken place along with proper management,” said Surya Kumar.

The Government wanted to sell the company to a private firm in Bengaluru and all formalities had gone through but the untimely demise of the private firm owner stalled the sale, he added.

Ananthapadmanabha, electrical section in-charge of the company, said that Komal was a two-speed moped which had two batteries of 12 volts. It had three relays manufactured by Bosch, a charging unit and each vehicle had a pricing of about Rs. 6,000.

“There were funds and infrastructure but there was no proper leadership. Eventually the company closed,” he said.

The company had participated in various auto expos at Toronto, Atlanta and Washington in 1981. Many were astonished that a developing country was manufacturing electric vehicles without seeking any help from developed ones, Ananthapadmanabha said.

Battery disposal

Going by the number of electric vehicles that are being purchased now, every house will have an electric two-wheeler in about 10 years. “Batteries have life and need to be disposed of when dead. They contain hazardous chemicals and if they are disposed of casually or as a landfill they will contaminate soil and underground water sources. Battery disposal should be done scientifically to prevent such problems in future, he said.

The biggest environmental issue with lead-acid batteries involves the lead component of the battery. Lead is a heavy metal with potentially dangerous health impacts.

Lead-acid batteries have been in the market for quite some time while lithium-ion batteries have been just recently introduced. Electric vehicles run on lithium-ion or li-ion batteries that store energy and can be recharged. The batteries used in these vehicles — from two-wheelers to commercial vehicles and public transport buses — are largely the same.

EV batteries consist of multiple lithium-ion cells and modules which are made up of heavy metals such as cobalt, lithium, nickel and manganese. Lithium-ion batteries and their end-of-life management is not a new challenge. Mobile phones and other consumer electronics already use these batteries. However, with a policy push from the Government for electric mobility, the consequent rise in used batteries from EVs, if not recycled, will be an environmental threat.

I like this article. Is they are on business? If so I need a mobed immediately.