- Only one out of 13 water purifying plants in city uses modern leak-proof vacuum feed technology

- Staff not professionally trained to handle the highly sensitive job at MCC’s Vani Vilas Water Works

By Mohan Kayaka

Mysore/Mysuru: Lakhs of city residents get purified drinking water daily through Vani Vilas Water Works (VVWW), the drinking water arm of the Mysuru City Corporation (MCC). Thirteen chlorination plants have been set up at various locations to purify the water before it reaches the homes. After the recent chlorine gas leak near Yadavagiri Railway Quarters where 87 persons including children suffered breathlessness, cough, irritation in the respiratory tract, congestion in chest and nausea, Star of Mysore did a reality check of the 13 chlorination plants that purify drinking water.

The reality check revealed that the purifying plants need an urgent facelift with the upgrading of machines. Outdated machines are being used to infuse chlorine into drinking water and these machines are affecting the performance of such plants. The reality check also revealed that the employees who operate the sensitive plants are not professionally trained in any way and they have learnt the operations from their seniors.

The 13 chlorination plants are set up at Vani Vilas Water Works main office at Yadavagiri, High Level Reservoir (HLR) at Yadavagiri, Central Service Reservoir at Vijayanagar, German Press, behind J.K. Tyre factory, Melapura, Rammanahalli, Belagola, Devanur, Pinjrapole near Udbur Gate and at Kembalu near Hullahalli.

Removing dangerous bacteria

As water gushes into Mysuru from Krishna Raja Sagar (KRS) and Kabini Dams, it is primarily treated at treatment plants and purified with chlorine before it is let out for human consumption. To prevent contamination with germs, disinfectants — usually either chlorine or chloramine —are added that kill disease-causing germs such as Salmonella, Campylobacter and Norovirus.

Chlorination is the process of adding chlorine to drinking water to kill parasites, bacteria, and viruses. Different processes can be used to achieve safe levels of chlorine in drinking water. Using or drinking water with small amounts of chlorine does not cause harmful health effects and provides protection against water-borne disease outbreaks.

Vacuum feed, gravity feed process

The employees at VVWW use two processes to mix chlorine to drinking water — vacuum feed and gravity feed — and there are dedicated machines to infuse the chemical. Compared to the gravity feed process, the vacuum feed process is considered modern and in Mysuru, only the Pinjrapole (near Udbur Gate) purifying unit uses this modern technology while the rest are outdated. The vacuum feed process stops on its own even if a small hole is detected in the supply pipes and has regulators to prevent chlorine leak. But the gravity feed process does not have such safety mechanisms. Chlorine gas is extremely dangerous and requires specialised handling. As 12 chlorination plants use the gravity feed process, there is a constant danger of leakage.

Untrained staff

Shockingly, the people who manage chlorination are not professionals and they do not have any sort of operational training. While many of them have 10 to 15 years of experience, the rest are novices with just one or two years of experience.

The tricks of the trade have been passed on to the juniors by senior staff and here too, the professional approach is missing with trial-and-error methods being employed to manage the sensitive job.

Thirty-five 900-kg cylinders per month

Each chlorination plant has over six to eight employees and they function in three shifts. One person has to constantly be present (24×7) near the chlorine cylinder as it needs to be switched off as soon as the electricity supply is cut.

Over 30 to 35 chlorine cylinders are needed per month to purify the entire drinking water in Mysuru and each cylinder weighs 900 kgs. One cylinder will last for 30 days and each chlorination unit needs two to three cylinders per month, VVWW Assistant Executive Engineer Mohammad Mustaffa told Star of Mysore. The cylinder supply contract has been given to Southern Chemicals that ensures constant supply of cylinders and the company staff supplies the chlorine cylinders to each chlorination plant.

Rs. 20,000 per cylinder

G. Bheema of Southern Chemicals said that the employees involved in the process of infusing chlorine into the drinking water are trained to operate the valves of the cylinders to prevent the chemical from leaking. Enough precautions are followed while operating the cylinders and only after employees are trained for one year, they are allowed to operate the cylinders, he claimed.

He said that the chlorine cylinders are manufactured in Andhra Pradesh and the factories at Kurnool and Rajahmundry supply cylinders to the entire South India. Each cylinder costs Rs. 20,000. “We take back cylinders even if they are full once every two months and the entire cylinder is checked once every two years for wear and tear,” he said.

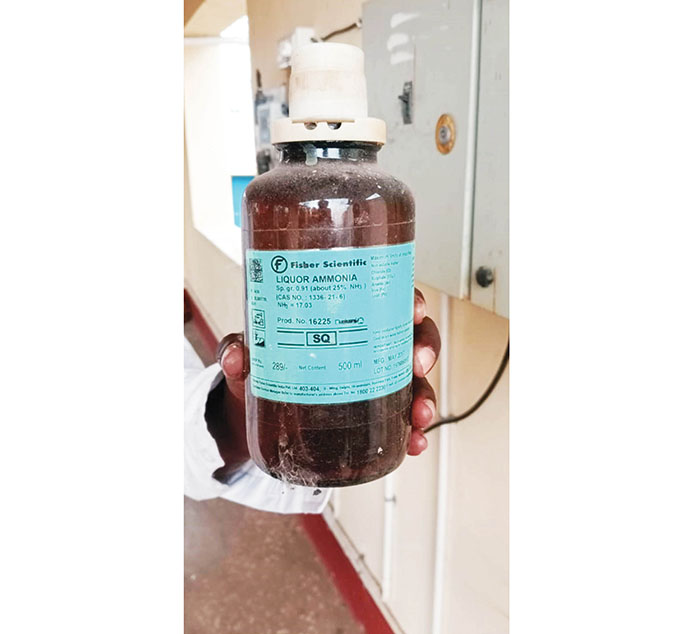

Checking leakages with liquor ammonia

Before each chlorine cylinder is fixed either to vacuum feed or gravity feed machines, liquor ammonia (strong solution of ammonia in water) is applied to the cylinder valves to check leakage. The liquid is not touched with bare hands and the staff use a cloth-wrapped stick and immerse it in the liquor ammonia bottle. After the cloth catches liquor ammonia, the stick is pulled out and the chemical is applied to the valves. Smoke comes out of the leaking spaces indicating the leak. This process is repeated each time when the chlorine cylinders are loaded onto the machines.

Negligence led to chlorine gas leak

“The chlorine gas cylinder that leaked at the Railway Colony in Yadavagiri recently is due to lack of maintenance. The cylinder there was lying unused and it was full. Its valve broke and there was a sudden outburst of the poisonous gas. Fortunately, there were no casualties and everyone has recovered now.” — Ghouse, Pump Operator, Vani Vilas Water Works

Vacuum feed machines in 6 months

“Vacuum feed machines will be installed at all the water chlorination plants in Mysuru in the next six to seven months. Each machine will cost Rs. 8 lakh to 10 lakh and the tender process has already begun. Approximately we need Rs. 1.20 crore to replace all the gravity feed machines.” — Mohammad Mustaffa, Assistant Executive Engineer, Vani Vilas Water Works

Recent Comments